For consistent quality of the end product, it is imperative that the raw material is as homogeneous as possible. Mixing/homogenization silos from ACHBERG are used for recycling and compounding of plastics. We select the optimal mixing process for you based upon the bulk material and the mixing quality required.

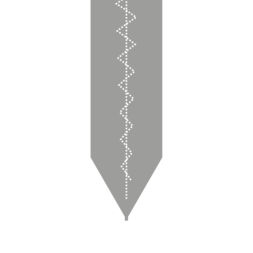

The screw mixing silo is used either in continuous mode as a continuous mixer or in batch mode. In batch mode, mixing takes place already during filling at individually adjustable time intervals. For this reason, the mixing time after filling is short. The mixing silo is used to mix free-flowing plastics in the form of regrind, granules or regranules.

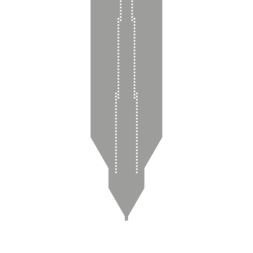

This homogenisation silo is used, e.g. for PVC dry blends as well as for other bulk materials with good to limited free-flow characteristics. The homogenisation process can be carried out continuously or sporadically. In irregular mode, conveying is required. It can be easily integrated in procedural processes.

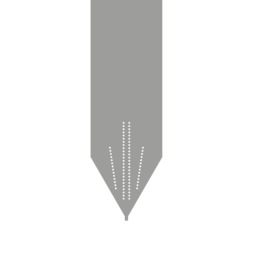

This homogenization silo is used to homogenise batches of free-flowing plastic granules. The homogenisation process can be carried out continuously or sporadically. In irregular mode, conveying is required. In continuous mode, the fill level must be at least 15-25%, depending on the size of the silo. A single pass is usually sufficient to homogenise the fluctuations in the melt index (MFR). In this case, gravity transports the bulk material to the outlet of the silo without requiring any additional energy.