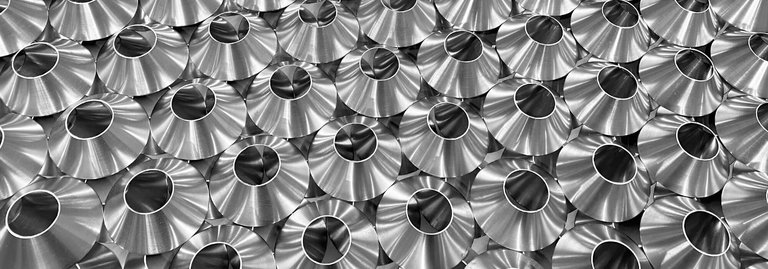

Our existing customers from the mechanical and plant engineering industries have been using our extensive production facilities for many years. Our services start with the optimisation of your part design in order to enable cost-effective series production with a high degree of automation with the highest quality and repeatability.

Upon conclusion of a blanket order, we ensure that contractually agreed batch sizes are ready for delivery from stock. We bear the costs for the inventory and storage and you only pay for the goods upon delivery.

Benefit from our modern machine park and our latest production techniques as well as from highly qualified employees, whom we have successfully trained for many years in terms of professional competence and quality awareness.

Partner with a powerful company for your long-term success!

ELECTRICAL ENGINEERING

PROTOTYPING

LOGISTICS